-

Overcoming a Broken Caliper Bolt - Trial, Error, and Frustration 2001 Toyota Tundra

Published: Tuesday, November 25th 2025 12:35:15 PM - EST

Updated: Tuesday, November 25th 2025 01:56:51 PM - EST

Written by: jbick

Category: AUTOMOTIVE

How I overcame a broken caliper bolt stuck into the knuckle assembly of my 2001 Toyota Tundra.

Buy Featured Items

With winter upon us and my need to collect recyclable lawn tractors, I decided it was time to purchase a 2001 Toyota Tundra. In 2025 a 2001 model of anything is very dated however Toyota's are known for reliability even at an older age.

In my case the frame of the truck, originally produced by DANA manufacturing had been replaced by the dealership so minimum rust in that regard. The truck ran/ runs fantastic for having 175,000 miles.

The truck was not without issue however. The brakes were super sponge-y and the FM radio antenna was broken. The threads were broke into the FM fixture. I had to replace that and both front calipers and both rear wheel slave cylinders. I also had to replace some break line.

These are minor issues or at-least in theory. The front calipers bleeders were seized up - being super rusty. I was unable to find replacement bleeder screws and the existing ones were very rusty. Toyota used small bleeder screws with 8 mm wrench size. The existing screws were so rusted I was unable to remove them - even with an extractor kit and torch. I could not break the bleeders so as to bleed the break system. So I went ahead and purchased two (2) new calipers off Amazon. I got 2 calipers for Toyota Tundra 2001 model off Amazon for a fraction of the cost of one at the parts store: i.e AutoZone, O'rielly, or Advanced auto.

I thought OKAY replacing a caliper is easy! Not so fast! I broke a bolt on the driver side caliper! Although the passenger side went no problem I screwed myself on the driver side. The bolt had broken inside of the knuckle. I had been watching a YouTube tutorial that said to use an air impact to remove the caliper bolts - so I did!

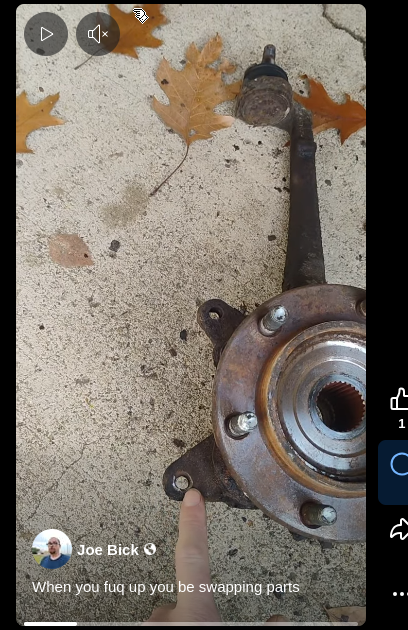

Using the impact was a life ending mistake. It broke one of my two caliper bolts. I had to use a saw all to get the caliper off considering the broken bolt. At this point the bolt was broken into the knuckle itself.

In the Toyota Tundra 1st gen's case: the caliper is bolted directly to the knuckle as opposed to having a bracket assembly with the pins. The caliper simply has two large bolts that thread right into the knuckle. It's up for debate whether this is better than that of a bracket assembly. It least with the bracket assemblies you can purchase new pins - which contain the bolts threads.

I thought no problem I will just drill out the bolt and put in new threads. That did not work - it took hours just to drill out the bolt which was only a small hole. At which point I had to resort to a die grinder just to clean the hole.

At this point I am SOL or Shit Out of Luck. I got the caliper off but how do we secure the new one? I tried taping threads into the knuckle but that proved to be unsuccessful even after fully drilling out and cleaning the bolt hole. It would seem the metal that the knuckle assembly itself is made out of is to hard to drill or tap threads - at-least without a lot of heat and machinery.

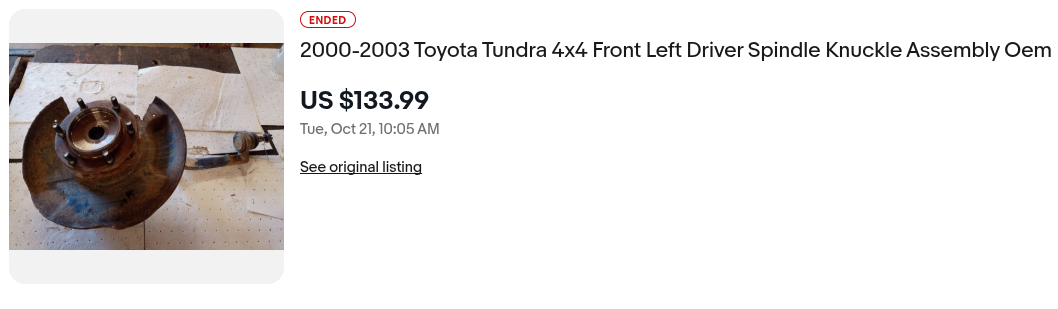

By this point the knuckle assembly left side would have to be removed regardless. I decided to just purchase a whole new used left side knuckle off eBay. I purchased a knuckle that came off of a Toyota 4Runner. It went right onto my truck and I was able to secure the break caliper with original bolts. YAY my truck is back in operation - with good breaks for the upcoming Michigan Winter.

Why I went with a new USED knuckle as opposed to just taping threads

- Awkward position to hold the tap.

- The knuckle assembly is that of super hard metal. It's basically impossible to tap threads. It took hours to drill out the broken bolt. :(

- The lack of proper tools. Although I have many thousands of dollars in tools, I lacked tough drill bits and adequate mechanism to drive the tap.

Things I had to purchase to replace knuckle and caliper

- New cotter pin kit. All the cotter pins on the old knuckle were very rusty. Any pin I had to torch out had to be replace. I bought a kit at autozone for $5.00.

- New caliper bolt for the one that I broke. I purchased off partsgeek.com

- Anti-sieze for all bolts to save myself in the future.

- A new break line that goes from the knuckle to the caliper.

- a cv axle socket kit so I could remove the old knuckle from the truck. I unfortuantely did not have a 35 mm socket on hand.

Benefits of using a new/used part

Just buying knuckle used online saves me the process of pressing in wheel bearings and it's good for the planet. It also already had the upper ball joint pressed. Lastly it saves me a lot of time, money, an labor costs.

- Saves time. the ball joint and wheel bearing are already pressed in. All I had to do was just slide the CV axle in bolt everything up and go.

- Saves money.

- Shipping Costs. It cost me $22.00 USD for shipping of the part.

- Unknown mileage on the used part. Although the part visibly appears better than the part I pulled off the truck it is still un-known how long it will last.

- Never blindly follow a YouTube video. Use judgment and prior experience before just popping on a impact driver.

- Use anti-sieze stuff on stubborn bolts so that in the future the bolt will break free with a ratchet by hand. In years past I would just take the bolt out and put it back to where it came from. I went and purchased anti-sieze for this project and all projects going forward.

- Utilize torch heat if any bolt is being stubborn. Had I of broken out my torch for this project and used a ratchet as opposed to an air impact I would not have broken the bolt in the first place.

Concerns with using a used knuckle

Lessons to takeaway

Caliper Replacement: Links

I got a pair of calipers off Amazon for the cost of one at the local parts store. I coudnt decide if the truck was worth replacing the calipers or rebuilding them however at the cost of a pair off Amazon I coudnt resist.

Related AUTOMOTIVE Posts